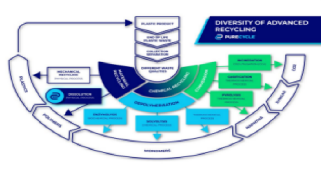

Types of Recycling

Firstly, I will explore several prioritized types of recycling

technologies used to recover important materials for future production.

-

Pyrolysis

Pyrolysis is a costly and hazardous treatment used to take apart

composite materials at high temperatures without oxygen. This process

extracts fibers from CFRPs and GFRPs and produces valuable by-products

that can replace oil and be used in mixed polymer recycling. This

treatment requires post-pyrolysis char removal and has high process

costs.

-

Mechanical Recycling

In mechanical recycling, the process of crushing, shredding, or

milling fiber-reinforced plastics (FRPs) separates fiber and resin-rich

partitions. These parts can be used as substitutes in new production.

The commonly used product, glass, is part of the glass fiber-reinforced

plastics (GFRPs) and carbon fiber-reinforced plastics (CFRPs). This

makes mechanical recycling cost-efficient and suitable for high

throughput rates. However, it can lead to economic and fiber property

loss by disrupting the physical integrity of fibers.

-

Chemical Treatment

The two main chemical treatment techniques, solvolysis and

supercritical solvolysis, produce high-quality fibers with good

mechanical strength. Solvolysis is less toxic but requires a large

number of solvents, which may alter the efficiency. Supercritical

solvolysis is cost-efficient and produces clean fibers but is more toxic

for the environment compared to solvolysis.

-

Fluidized-Bed Processing

This process achieves fibers from CFRPs and GFRPs at their highest quality by treating composite materials in a fluidized bed at extreme temperatures with less economic cost. Although this method has low economic viability, mechanical processing releases fewer pollutants, making this method less environmentally friendly.